How to Work With Rose+Krieger Aluminum Extrusions

When a project’s physical size goes beyond the use of traditional project boxes and enclosures, custom extruded aluminum frames fabricated from DigiKey’s Structural and Motion Hardware category are a good choice for every skill level.

(Image source: Rose+Krieger)

(Image source: Rose+Krieger)

One of the great things about aluminum extrusions, aside from being strong and lightweight, is the anodized finish which is smooth and durable with no need for painting. Another attribute is ease of fabrication. If you have a carbide tipped, high tooth count blade in a chop or radial arm saw, you are ready to start fabrication.

Note: A blade with one hundred or more teeth is highly recommended and if available, lubricate the blade with solid stick cutting lubricant found in many hardware stores or building centers. Filing rough edges, drilling and tapping operations are also easy with aluminum. If you have a CNC router or milling machine, aluminum cuts cleanly.

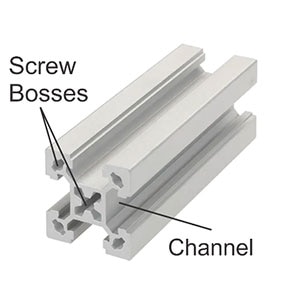

Most aluminum extrusions employ built-in screw bosses for locating and fastening hardware and channels for securing panels, hinges, fixtures and lighting or brackets for joining pieces together. Let’s take a closer look at how this joint is made.

(Image source: Rose+Krieger)

(Image source: Rose+Krieger)

The most common method to join Rose+Krieger aluminum members uses the 90-degree flange bracket kit. The bracket is secured on end profile of an extrusion using the center screw boss; then it is aligned to the bracket with a channel on another extrusion. Finally, the two stones are installed and secured with two screws. That is all it takes to make a strong, secure joint. Simply repeat the process for all other joints to construct a complete frame.

(Image source: DigiKey)

(Image source: DigiKey)

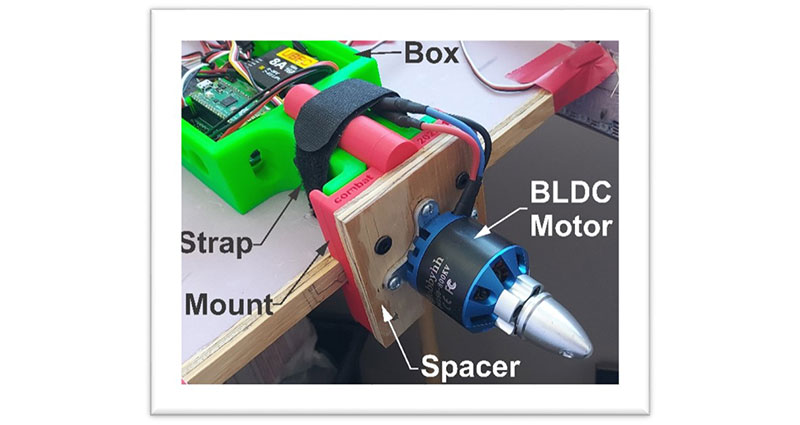

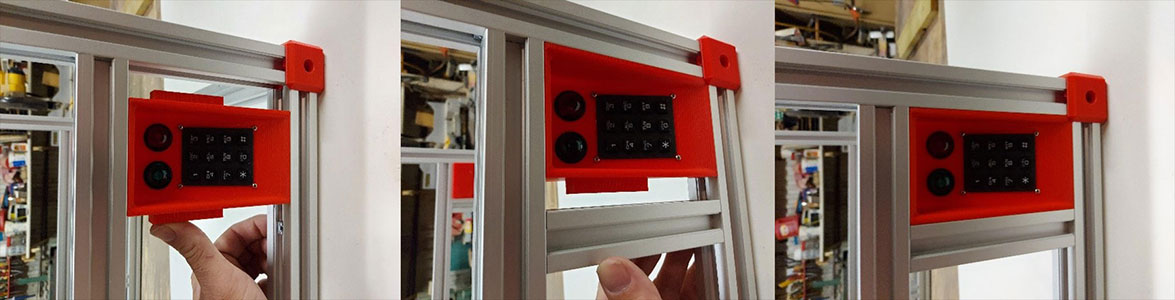

As mentioned earlier, the extrusion’s channels are useful for mounting accessories such as LED strips and 3D printed pieces. By adding a flange to a 3D print, it can be trapped in the channel neatly and securely without additional fasteners. LED strips conveniently slide right into the channel and may be secured with a Rose+Krieger clear cover if desired. Lastly, wooden, plastic or composite panels cut to the right size may also be trapped in the channels to create walls, floors, ceilings, and hinged panels.

(Image source: DigiKey)

(Image source: DigiKey)

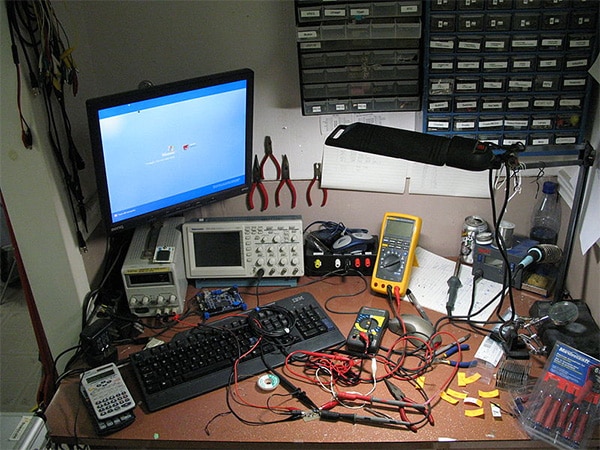

There’s an endless number of uses and configurations for this material to make clean, professional looking projects such as work benches, test fixtures, robots, and 3D printer and CNC frames, etc. DigiKey carries a wide variety of extruded structural hardware by Rose+Krieger. The 30 mm by 30 mm Frameworks® series was ideal for this example project.

(Image source: DigiKey)

(Image source: DigiKey)

BOM:

| 1 | 1758-1000-ND | ZY3120 | 1 m extrusion |

| 20 | 1758-1018-ND | SL16915 | Flange bracket connectors |

| 1 | 1942-1076-ND | RM-PL0127 | Red 3D filament |

| 1528-1092-ND | LED strips | ||

| Clear Cover | |||

| Aluminum cover | |||

| 8 | H756-ND | MPM 005 0025 PH | 25 mm x M5 screw |

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum