LED Connectors Help Designers Meet SSL Cost, Performance Requirements

Bidraget af Electronic Products

2014-02-04

As solid-state lighting (SSL) system designers look to develop cost-competitive solutions, while still maintaining high reliability in their fixture designs, they are turning to connector manufacturers to provide dependable miniature parts that also feature cost-saving innovations. Interconnects used in these systems not only can provide the electrical connection to the drivers and array modules, but they also provide mechanical support.

A variety of interconnects, ranging from edge-card connectors to discrete wire connectors, are available to the LED lighting designer. In some cases, existing board-to-board and wire-to-board connectors also can be used for these applications. On the other hand, many connector solutions are designed specifically to meet the lighting designer's requirements.

However, because there are no real standards for connectors in the LED lighting market, manufacturers of LED holders or sockets typically develop special devices for each LED manufacturer. A consortium called Zhaga is working to develop specifications that allow for the interchangeability of LED light sources made by different manufacturers. The Zhaga specifications describe the interfaces between LED luminaires and LED light engines. This effort should simplify the design of general lighting applications. A few connector manufacturers, including Molex and TE Connectivity, have joined the global organization.

This article will help lighting designers answer the question of what connectors to use in their latest fixture design by examining what major suppliers have to offer in LED connector solutions that have been adapted for the LED industry or designed specifically for SSL.

A sampling of solutions

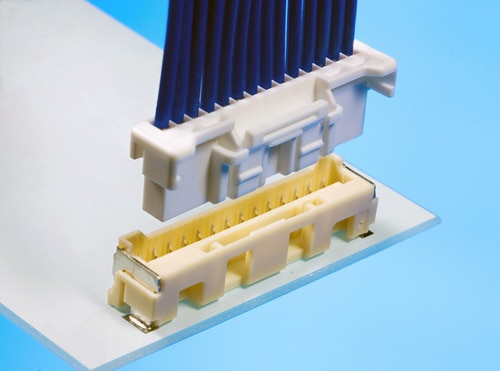

Initially designed for harsh industrial and automotive applications, the AVX 9175 and AVX 9176 (Figure 1) insulation displacement connector (IDC) series with their small size and high reliability can be used in a broad range of applications including solid-state lighting. The redesign of the surface-mount wire-to-board IDCs simplifies the wire termination process and reduces its cost.

Figure 1: AVX redesigned their low-profile 9175 and 9176 IDC series to simplify and reduce the cost of wire termination processes in SSL applications (Courtesy of AVX).

The one-piece design of the IDC series enables users to insert discrete wires into the cap without stripping them first, and to simply press the cap down to provide a secure gas-tight termination. Advantages over other IDC types, according to AVX, include a higher current rating, a higher voltage rating, a higher allowable maximum temperature, a lower profile, and smaller footprint. It also offers an end-stop cover option, and an option to support smaller wire gauges.

TE Connectivity (TE) also offers an IDC SSL connector. It enables tool-less termination of discrete wires onto LED PCBs, and terminates 18 to 24 AWG solid and stranded wire using insulation displacement technology to eliminate the prestripping and soldering processes. The connector can be used in lighting controls, general illumination LED fixtures, and connecting strings of PCB LED light modules. It also can be used in nonlighting wire-to-board applications.

TE’s IDC SSL connector is available in several versions including SMT/through-hole and closed-end/feed-through configurations. For example, the closed-end version offers a "viewing" window to ensure that the wire is fully seated and secure after termination. It also features rounded corners to minimize shadowing. The connector is available in one, two, three, and four positions.

AVX's 9296 series (Figure 2) of wire-to-board connectors is designed for industrial and SSL applications. The company touts the interconnect as the first vertical, top-mount, SMT wire-to-board connector specifically designed to meet the configuration, performance, and cost requirements of industrial and SSL design engineers.

Figure 2: The 9296 series of wire-to-board connectors from AVX is designed to meet the configuration, performance, and cost requirements of SSL and industrial design engineers (Courtesy of AVX).

The 9296 connectors feature AVX's dual-beam, 3 mm high, spring-force box contacts, packaged in a protective insulator. The 9296 series poke-home connectors are said to provide maximum mechanical stability and wire retention, along with simple strip and insert wire loading and twist-and-pull wire removal. The one- to six-way connectors also allow users to insert solid or stranded, plated or unplated 18 to 26 AWG wires directly through the connector's top aperture.

Other products in the 9296 family include the 70-9296 wire-to-board, dual-beam, closed-box contacts. These insulator-less contacts are available in 2, 3, and 4 mm sizes and accommodate solid or stranded wires ranging from 12 to 28 AWG with current ratings up to 20 A. Key features include high force retention, easy wire guidance, easy wire removal, and lower cost by eliminating the labor and materials costs related to the insulator.

Also designed for several applications is Molex's CLIK™-Mate series of wire-to-board connectors (Figure 3). These connectors are designed for applications that need higher pin counts to carry more signal lines in less space. They are available in pitch sizes of 2.00, 1.50, and 1.25 mm. The 2.00 mm version offers the highest-current-carrying capability of 3.0 A and 250 V.

Figure 3: Molex's CLIK-Mate wire-to-board connectors feature a tuning-fork terminal design that provides low insertion force and secure mating, together with higher pin counts for designs that need more signal lines in less space (Courtesy of Molex).

The CLIK-Mate features a tuning-fork terminal design that delivers a low insertion force and a secure mating contact. SSL applications include commercial lighting fixtures, LED light modules, and office down lights. They can also be used in automotive applications such as head lamps and interior mirrors, gaming machines, LCD and TV panels, and medical devices such as glucose meters, infusion pumps, and instrumentation.

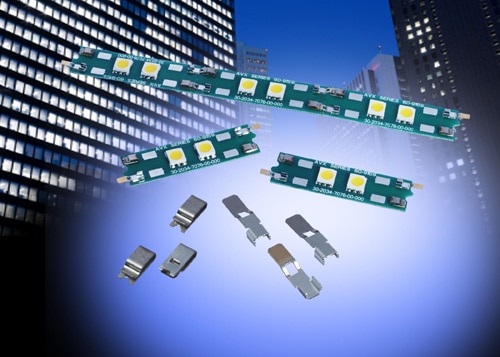

AVX’s board-to-board 9159 series connectors (Figure 4) are designed specifically for linear LED lighting. These connectors allow two printed-circuit boards (PCBs) to be mated end to end, creating strips of LED lighting. The design meets SSL requirements for coplanar (horizontal-to-horizontal) PCB mating with a 5 A current rating in a very small package.

Figure 4: AVX's 9159 series allows LEDs to be placed down the center of the PCB to maximize light output in SSL strip lighting (Courtesy of AVX).

One of the newest products in the 9159 family is the 70-9159 horizontal contact system, which offers a 5 A current rating. Key features of the coplanar, connector-less contact system include a gold-to-gold active contact interface for contact integrity in rugged lighting environments, and support for board-to-board and wire-to-board applications. The company said the contact system also absorbs significant x- and y-axis assembly tolerances.

AVX further said this new system allows LEDs to be placed down the center of the PCB to maximize light output in SSL strip lighting, as well as to minimize LED pitch densities by removing the insulator from the connection solution. It also allows the contacts to be placed individually on the outer edges for higher functionality and lower costs. Contact height is 1.2 mm above the PCB.

Also designed as a miniature and cost-effective solution for lighting engineers, AVX's 00-9159 open-ended card-edge connector meets the design engineer's requirement for a high-density pin-count solution and a smaller size for linear LED strip lighting. The connector is designed without plastic end-walls to minimize length, said AVX, and offers a double-sided configuration for increased pin-count density. Other features include a central keying rib for improved strength and alignment, and a tin-to-tin contact interface for cost savings.

This solution is used to connect two in-line PCBs in linear LED strip lighting. It offers 4, 6, 8, or 10 contact positions, has a voltage rating of 300 VAC, and measures 1 mm in length per number of contacts.

Another example of a card-edge connector designed for LED lighting applications is TE Connectivity's ITB (Inverted Thru-Board) interconnect (1971748 series). The ITB card-edge connector provides direct power connection for board-to-board mating from the driver boards to the underside of LED array boards. The direct mating eliminates wire routing in assemblies. In addition, the connector is surface-mounted at the same time as other devices on the PCB to eliminate secondary processes, and is designed with rounded corners to minimize shadowing from the light-emitting surface, according to TE.

Aimed at compact LED assembly designs, such as retrofit lamps and bulbs, the two-position SMT connector provides perpendicular mating when top-mounted on an array PCB, making it suitable for space-constrained designs. The 1.5 mm height above the PCB is said to minimize LED light obstruction while saving space. It is available in two versions to accept 1.0 mm or 1.2 mm-thick boards.

Although the interconnect targets LED replacement lamps as well as indoor and outdoor LED lighting fixtures including spotlights, down lights, and track lights, the ITB also can be used in nonlighting applications that call for a cable-less space-saving inverted board-to-board interconnect.

TE Connectivity also offers a low-profile connector for space savings in outdoor LED lighting applications. The one-position SlimSeal connector provides an IP67-sealed, daisy-chained power connection between multiple LED modules in a single light fixture and the power source. The connector is available in one, two, three, and four positions and accepts 18 to 20 AWG and 22 to 24 AWG stranded wire.

Hirose also offers a series of SSL connectors aimed at space savings. The DF series offers wire-to-board, board-to-board joint, and in-line connectors for SSL fixture applications. The connectors feature space savings, high cable pull force, and a secure connection. The DF series connectors, comprised of the DF57, DF59, DF61, and DF62, deliver a variety of connector solutions for designers of lighting fixtures, SSL arrays, and LED bulbs.

The DF57 series of wire-to-board connectors offers a 1.2 mm pitch and 1.4 mm height with a current capability of 2.5 A. The low profile makes it suitable for connecting LED drivers to lighting fixtures. It also features a unique double “swing lock” design that ensures positive and friction locks.

In addition, the DF59 series 3-way system connector, featuring the “swing lock” design, offers a 2.0 mm pitch and “stress free contact” to provide 0.5 mm floating function in xyz directions. Three selectable types of headers mate to the connector's one common socket for wire-to-board, board-to-board joint, and short-circuit pin. These connectors can be used in linear SSL applications.

Targeting LED light bulbs and tube fixtures, the DF61 series connectors offer a 5 A current capacity. These connectors can be vertically mated despite its low profile. They are available in straight, right angle, and in-line connection styles.

The DF62 series in-line connectors feature box-shaped female contacts that work as a mating guide for male contacts, an arrangement that is said to virtually eliminate contact buckling. These connectors are used in applications that have narrow or confined cabling requirements.

In the LED holder or socket segment, assemblies are typically designed for specific manufacturers. Molex offers a family of chip-on-board (COB) holder assemblies that can be used with Citizen, Bridgelux, Cree, Sharp Zenigata, and Nichia LED arrays. These devices are used for the electrical connection and mechanical support of the LED arrays.

Molex also offers the Pico-EZmate™ harness (Figure 5) for Bridgelux Vero LED arrays. These harnesses, using the Pico-EZmate connector technology, are said to provide the lowest-profile interconnect for SSL when used with an integrated header feature in select LED arrays.

Figure 5: Designed for space-constrained designs, the Molex Pico-EZmate wire-to-board connectors offer a low profile with a mated height of 1.55 mm for versions with two to five circuits and 1.65 mm for a six-circuit version (Courtesy of Molex).

The harness system minimizes handling of the arrays during installation, which reduces the chance of damaging the LED. They are offered in three wire-gauge configurations and three lengths for a range of harness options.

TE Connectivity offers LED sockets that fit a variety of LED arrays including those from Philips Lumileds (part 2154821-1), Citizen, and Samsung. These devices offer a higher level of integration with a solderless connection to array and COB LEDs. Like other LED holders, they provide the mechanical support and electrical connection from the LED to the luminaire. With this solution the LED is directly attached to the PCB or heatsink with a few screws.

TE Connectivity's “Z” series of holders allow customers to build Zhaga-compatible products. The Type-Z LED holders provide a solderless connection to LED arrays. They are available with or without optics. The optics attachment version works with Carclo or LEDIL optics for beam-shaping flexibility in spot and downlight applications, according to TE.

The Type-Z50 circular LED holder family may be used with the Philips Lumileds LUXEON® COB LED array family (20 x 24), Citizen Electronics’ CLL030/032, and Samsung’s LC026B/LC040B LEDs. They also feature snap-in LED retention to ensure proper positioning in the fixture.

Similar to other products, the Type Z50 provides an integrated poke-in electrical connection to eliminate hand soldering and therefore reduce costs. In addition, the snap-in LED retention makes it easier to handle during installation.

The Z50 holder measures 3 mm in height with a 45 mm diameter, which makes it suitable for omnidirectional and custom optic applications. They can be used in a variety of fixtures including spotlights, down lights, stage lights, wall washers, and architectural lighting.

In summary, as LED lighting adoption continues to grow in both commercial and residential lighting applications, connector manufacturers are ramping up their interconnect development to offer more solutions that meet a lighting designer's requirements for performance and cost. Going forward, in addition to providing reliable power connections, connector makers will likely focus on miniaturization to fit space-constrained applications. They also will keep in mind the need to control costs by continuing to develop features that eliminate or simplify processes.

For more information on the parts discussed in this article, use the links provided to access product information pages on the DigiKey website.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.