LED Breakthroughs for Retrofit Lamps

Contributed By Electronic Products

2014-01-28

Designers of retrofit lamps face several lighting challenges that center on size, luminous efficacy (lumens per watt), thermal issues, and cost requirements. As a result, LED component manufacturers continue to develop new package styles and technologies to deliver improved light extraction and increased conversion efficiency that also help drive down costs.

Driven by growth opportunities in the lighting market as backlighting growth wanes for LED component manufacturers, only 2.8 percent, or 520 million lamps, of the total 18.6 billion lamps shipped in 2013 are forecast to use LED technology, according to market research firm IHS, Therefore, suppliers have great incentive to address retrofit product development issues. Overall, IHS expects demand for LED lighting to drive revenue growth of $2.5 billion during the next five years.

Particularly in the consumer retrofit lamp market, one of the barriers has always been the cost of the lamps, according to Paul Scheidt, product marketing manager at Cree Inc. The company's message is lower-cost LEDs without sacrificing quality as a way to achieve cost goals. "You need a lamp that looks and performs like the product that is being replaced," Scheidt said. "You can't expect people to downgrade their lighting experience and pay more for it."

"That has been one of the challenges," Scheidt added. "Technically, how do you continue to reduce the cost of the system without sacrificing the look or performance of the lamp within the whole system?"

Several of the bigger players in the market, including Cree and Philips Lumileds, have already made some strides in developing LEDs that target retrofit lamps including MR16 and PAR styles. Many of the designs, including a few from Cree and Philips, focus on a combination of smaller packaging, better phosphor, and new methods to achieve lower cost and higher performance.

As an example, Cree points to their SC3 technology platform that delivers on performance and cost. The LED technology platform features silicon carbide LEDs for improved light extraction, new phosphor for increased conversion efficiency, and new packaging for better light extraction and low thermal resistance. The key driver behind the technology development, initially launched two years ago, was to double the lumens per dollar of any of their previous LEDs. The push aimed at delivering the same performance and high reliability light, but at a much lower price point.

Scheidt explained that the SC3 technology is all about optimizing three major systems: the LED chip, LED package, and phosphor, and bringing those improvements to new and existing products. "It really speaks to that main challenge of reducing the cost of light without sacrificing quality," said Scheidt. "To pay less and get less is pretty easy, but to get the same or better performance at a lower price is the name of the game."

Over the past two years, Cree has taken a lot of that innovation that was first introduced with the XLamp XT-E product and applied it to other offerings, including the XLamp XP-G LED which was very commonly used to make PAR (directional) and MR16-type lamps. The company upgraded the performance of the part by about 15 percent with the SC2 second-generation technology, delivering greater lumens per watt.

One of Cree's latest products using the enhanced SC3 technology is the XLamp XP-G2 LEDs, which offer a seven percent increase in brightness compared to the existing family, delivering high light output and efficacy. The higher performance also enables the use of fewer LEDs in a lighting design to lower total costs. Cree said this translates into fewer optics, a smaller printed circuit board (PCB), and less handling.

The XP-G2 LEDs deliver up to 142 lumens per watt at 350 mA, 85°C, or 155 lumens per watt at 350 mA, 25°C in warm white (3,000K). This family can be used in a variety of applications including PAR replacement lamps and flashlights, as well as street and area lighting.

Cree reports that it has 6,000 hours of LM-80 long-term testing data for the XP-G2 LED. It provides TM-21 reported L85 lifetimes greater than 36,000 hours, which translates into a 15 percent light loss after four years, even at the maximum current of 1,500 mA. The company now presents more than 12,000 hours of LM-80 data for the XP-G2's predecessor, the XLamp XP-G LED. It provides TM-21 reported L95 lifetimes greater than 70,000 hours, or eight years, indicating long-term reliability of the XLamp XP package.

Another one of Cree's big innovations for PAR-type lamps is the extension of their CXA family of chip-on-board (COB) LED arrays with a high density (HD) version that is targeted to replace ceramic metal halide in directional applications. The HD LED array family is said to double the system intensity of spotlights compared to previous arrays. The first HD array, the CXA1520 LED (Figure 1), delivers the same intensity and light quality as a 39 W ceramic metal halide (CMH) at up to 50 percent lower power. This means it delivers a lot of light from a very small source, translating into lower system cost.

Figure 1: The CXA1520 high-density (HD) LED array offers the same intensity and light quality as 39 W ceramic metal halide (CMH) at up to 50 percent lower power (Courtesy of Cree).

"It's not just about the lumens, but about being able to pack the lumens in a very small space so you can control the light very well. It has been a challenge," said Cree’s Scheidt.

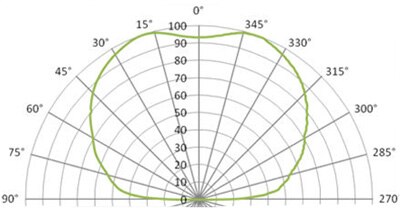

A new platform for 2013 has been Cree's XLamp XQ LED footprint (Figure 2), which is a very small 1.6 x 1.6 mm square package. It is available in two styles: the XQ-D and XQ-E. The XQ-D features a squared-off top so it works very well for retrofit lamps in order to help spread light out to create a more omnidirectional light pattern. The XQ-E provides a traditional rounded dome. It is more of a directional LED, and is packaged in the same small footprint, making it easier to pack more LEDs into a small retrofit lamp.

Figure 2: The Cree XQ LED features a breakthrough light-emission pattern that directs more light to the sides, enabling lighting designers to achieve omnidirectional design (Courtesy of Cree).

Philips Lumileds is also working to shrink package size while improving performance. One good example is the company's LUXEON T LED family, which is supplied in a small package with a low thermal resistance of 3°C per watt, while maintaining high color rendering (CRI) across the full correlated color temperature (CCT) range of 2,700K to 5,000K.

Building on their hot testing and ‘Freedom from Binning’ innovations, Philips Lumileds said the LUXEON T is tested and specified at 85°C to ensure performance with tight color control to within 3-Step MacAdam ellipse binning. This allows designers to achieve high system efficacy and flexibility to reduce the number of emitters in a design without compromising on high CRI across the full CCT range from 2,700K to 5,000K.

The LUXEON T delivers up to 140 lumens per watt at 350 mA, 85°C in neutral white at 5,000K 80 CRI minimum in a 3.7 x 3.7 mm package. It features high-center-beam candle power and precise optical control for narrow beams required in directional applications such as MR16 and PAR retrofit lamps.

Philips Lumileds attributes the LUXEON T LED's performance to the company's efforts in epitaxial growth that delivers leading wall plug efficiency and hot/cold factor (how much light is delivered at operating conditions, not at test conditions), new phosphors for enhanced conversion efficiency, and package optimization to achieve low thermal resistance and optimized light extraction. These LEDs are available in five different CCTs: 2,700K, 3,000K, 3,500K, 4,000K, and 5,000K, all specified at high-CRI, 80 minimum. The family is also available with 95 typical CRI and red rendering (R9) of 90, which makes it suitable for the professional lighting market.

Another example from Philips Lumileds is the LUXEON Z ES (Figure 3) micro-mini undomed LED platform that is 75 percent smaller with a high flux density, giving designers greater design flexibility and "best white color consistency," thanks to a 1-step MacAdam ellipse in warm white color options that delivers optical control in a small footprint. The LED also claims a 10 to 15 percent higher color over angle (CoA) compared to standard domed emitters for higher Quality of Light requirements in indoor applications, which makes it suitable for lamps such as GU10, BR30, and A19.

Figure 3: Philips Lumileds' LUXEON Z ES offers a micro-sized, undomed LED that delivers precise optical control and color consistency for directional light-source applications (Courtesy of Philips Lumileds).

The undomed design is also said to enable better optical coupling for greater luminance at narrower beam angles, and better color consistency than other LED solutions in directional light sources such as an MR16 lamp. In addition, the LED is available with 1-step binning, a key feature required for superior color perception in specialty retail and hospitality applications, according to Philips Lumileds.

The LUXEON Z and Z ES LEDs are available over a range of CCTs from 2,700K to 6,500K with 5-, 3-, and 1-step MacAdam Ellipse binning options. The small footprint means that manufacturers can use optical solutions that are 25 percent smaller, while offering the same light quality as larger, domed solutions, said the company. Different colors will be available including white CCT, lime, blue, phosphor-converted amber, and red.

In summary, lighting manufacturers typically have had to design around the size of the LEDs. Now that product is available in smaller package sizes, and with enhanced performance at lower price points, it opens up new design opportunities including the possibility of new form-factors.

For more information on the parts discussed in this article, use the links provided to access product information pages on the DigiKey website.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.